- Home

- Capabilities

- Product

Product

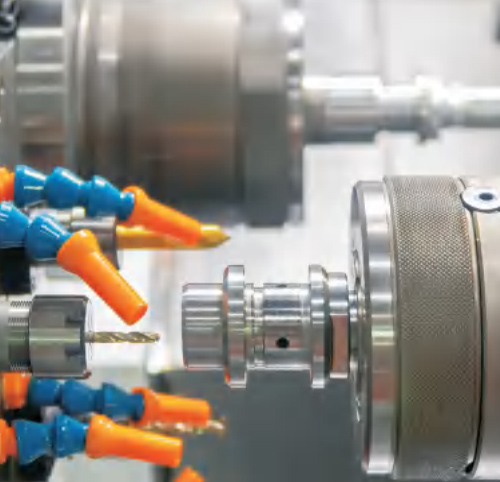

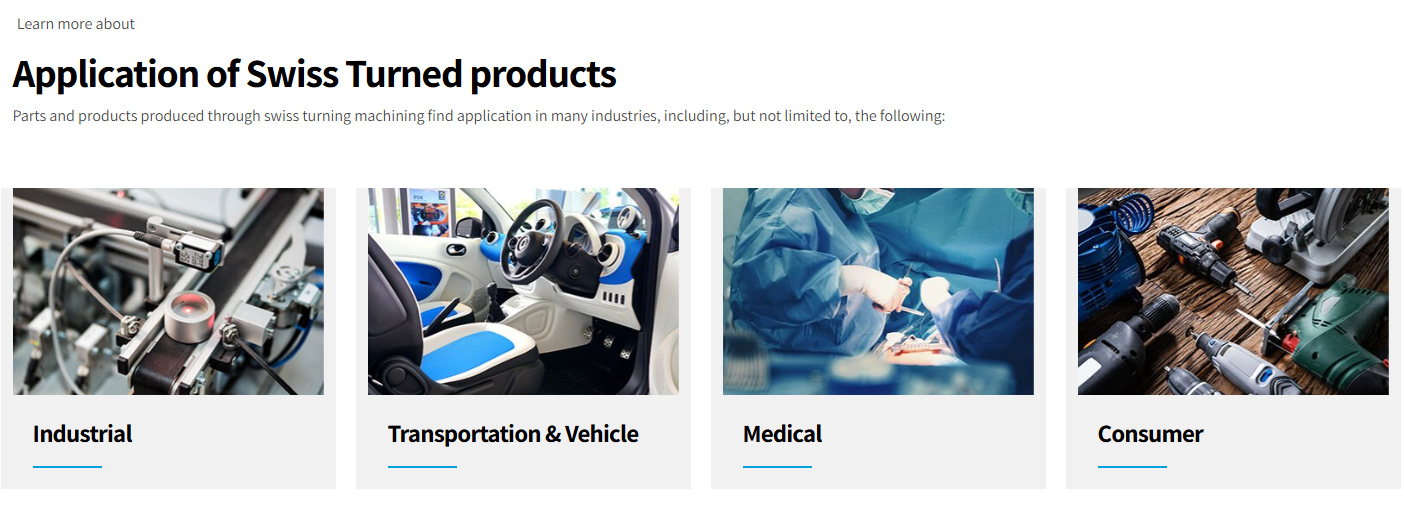

ProductIN PRECISION INDUSTRY. has extensive experience in professional CNC turning parts and precision metal parts processing, producing various medical parts, KOVAR components, optical communication metal parts, fiber laser metal parts, and precision parts manufacturing!

View More - Industries

- Materials

- Facility

- About us

About us

About usIN PRECISION INDUSTRY. has extensive experience in professional CNC turning parts and precision metal parts processing, producing various medical parts, KOVAR components, optical communication metal parts, fiber laser metal parts, and precision parts manufacturing!

View More - News

News

NewsFollow us to stay updated on the latest developments in precision hardware components production and processing.

View More - Contact us

- 136-8242-0657

Consultation hotline

-

Wechat

Wechat - Language

Tel:+86 136-8242-0657

Tel:+86 136-8242-0657 Website:http://www.xianjingcn.com/

Website:http://www.xianjingcn.com/ Address:No.20 Jiahui Road, Fenggang Town, Dongguan City

Address:No.20 Jiahui Road, Fenggang Town, Dongguan City Mobile Site QR Code

Mobile Site QR Code Mini Program

Mini Program